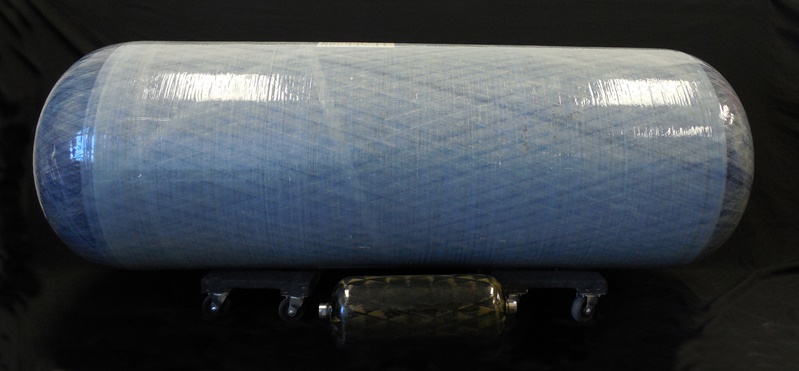

Natural Gas

HEI’s reputation within the space industry for Hydrogen COPV innovation attracted the world’s early adapters of Hydrogen for on-board use of automotive Hydrogen for fuel storage. HEI successfully supplied the first “proof of concept” extreme high pressure gaseous and cryogenic compressed Hydrogen automotive solutions to the global leaders of automotive OEMs in the early adaption of Hydrogen COPVs and their proof-of-concept success. We have successfully demonstrated capabilities in cryogenic compressed Hydrogen as well as very high pressure gaseous hydrogen, of which there is a representative top-level summary below. Specifics are available to our clients on a case-by-case basis.

• Design and Testing of Composite Hydrogen Tanks for On-Board Storage for the Automotive Industry.

• Superior Designs, Materials and Fabrication Techniques for Thick Wall Laminates.

• Light Weight, Safety-First Designs.

• Superior Pressure Cycle Life.

• Proven Toughness and High Impact or Damage Tolerance.

• Special Expertise in Pressure Sealing and Neck Design.

• Technology Based on New Materials and Fabrication Techniques Developed Under NASA Contracts.

Hydrogen

HEI’s reputation within the space industry for Hydrogen COPV innovation attracted the world’s early adapters of Hydrogen for on-board use of automotive Hydrogen for fuel storage. HEI successfully supplied the first “proof of concept” extreme high pressure gaseous and cryogenic compressed Hydrogen automotive solutions to the global leaders of automotive OEMs in the early adaption of Hydrogen COPVs and their proof-of-concept success. We have successfully demonstrated capabilities in cryogenic compressed Hydrogen as well as very high pressure gaseous hydrogen, of which there is a representative top-level summary below. Specifics are available to our clients on a case-by-case basis.

• Design and Testing of Composite Hydrogen Tanks for On-Board Storage for the Automotive Industry.

• Superior Designs, Materials and Fabrication Techniques for Thick Wall Laminates.

• Light Weight, Safety-First Designs.

• Superior Pressure Cycle Life.

• Proven Toughness and High Impact or Damage Tolerance.

• Special Expertise in Pressure Sealing and Neck Design.

• Technology Based on New Materials and Fabrication Techniques Developed Under NASA Contracts.

Oxygen

HEI’s reputation within the space industry for Hydrogen COPV innovation attracted the world’s early adapters of Hydrogen for on-board use of automotive Hydrogen for fuel storage. HEI successfully supplied the first “proof of concept” extreme high pressure gaseous and cryogenic compressed Hydrogen automotive solutions to the global leaders of automotive OEMs in the early adaption of Hydrogen COPVs and their proof-of-concept success. We have successfully demonstrated capabilities in cryogenic compressed Hydrogen as well as very high pressure gaseous hydrogen, of which there is a representative top-level summary below. Specifics are available to our clients on a case-by-case basis.

• Design and Testing of Composite Hydrogen Tanks for On-Board Storage for the Automotive Industry.

• Superior Designs, Materials and Fabrication Techniques for Thick Wall Laminates.

• Light Weight, Safety-First Designs.

• Superior Pressure Cycle Life.

• Proven Toughness and High Impact or Damage Tolerance.

• Special Expertise in Pressure Sealing and Neck Design.

• Technology Based on New Materials and Fabrication Techniques Developed Under NASA Contracts.